Electronic Batch Records: Extend Quality Oversight to the Manufacturing Floor

Digitization of life science manufacturing must go beyond the surface level and permeate deeper to every level of quality and compliance. The interconnectivity of systems and process integration facilitated by a holistic, cloud based QMS enables quality teams to adopt digital features across all their workflows, delivering value throughout.

Life science organizations are increasingly transitioning from manual to electronic batch records for improved efficiency and accuracy. One study documented a 75% decrease in human errors following electronic batch record implementation.

Ensuring the integrity of data in the life sciences is a key priority for the FDA. In its guidance document, Data Integrity and Compliance with Drug CGMP, the agency describes an increasing number of CGMP violations involving data integrity during CGMP inspections, which have led to “numerous regulatory actions, including warning letters, import alerts and consent decrees.”

The challenge to quality is that electronic batch records are typically maintained in the manufacturing execution system (MES) apart from the QMS. As a result, quality teams face an uphill battle to ensure products are manufactured in accordance with standard operating procedures (SOP) and identifying deviations when they occur. While they have evidence from batch tests, they can’t see the complete picture of whether all batches were manufactured in accordance with the batch master record steps.

With next generation QMS platforms featuring full integration with the MES, the quality team has full visibility into electronic batch records to manage the manufacturing process, while maintaining cGMP compliance.

They can see when a deviation arises and investigate it immediately. Here is a quick example: Let’s say machine A breaks down, but the deviation does not impact quality, and machine B is used in its place, as opposed to when machine B was used for a step while both machines were equally functioning properly, the quality team can release the batch with the exception and record why the decision was made.

On the other hand, if quality determines that the deviation could negatively impact product quality, such as when a key step in the SOP was skipped or performed incorrectly, they can hold the batch and pursue remediation.

Within the QMS, quality can link all relevant documents in the manufacturing process – the work instructions, SOPs, electronic forms, batch records, test results – and store them electronically in one place, for example, in an electronic binder for easy reference and sharing.

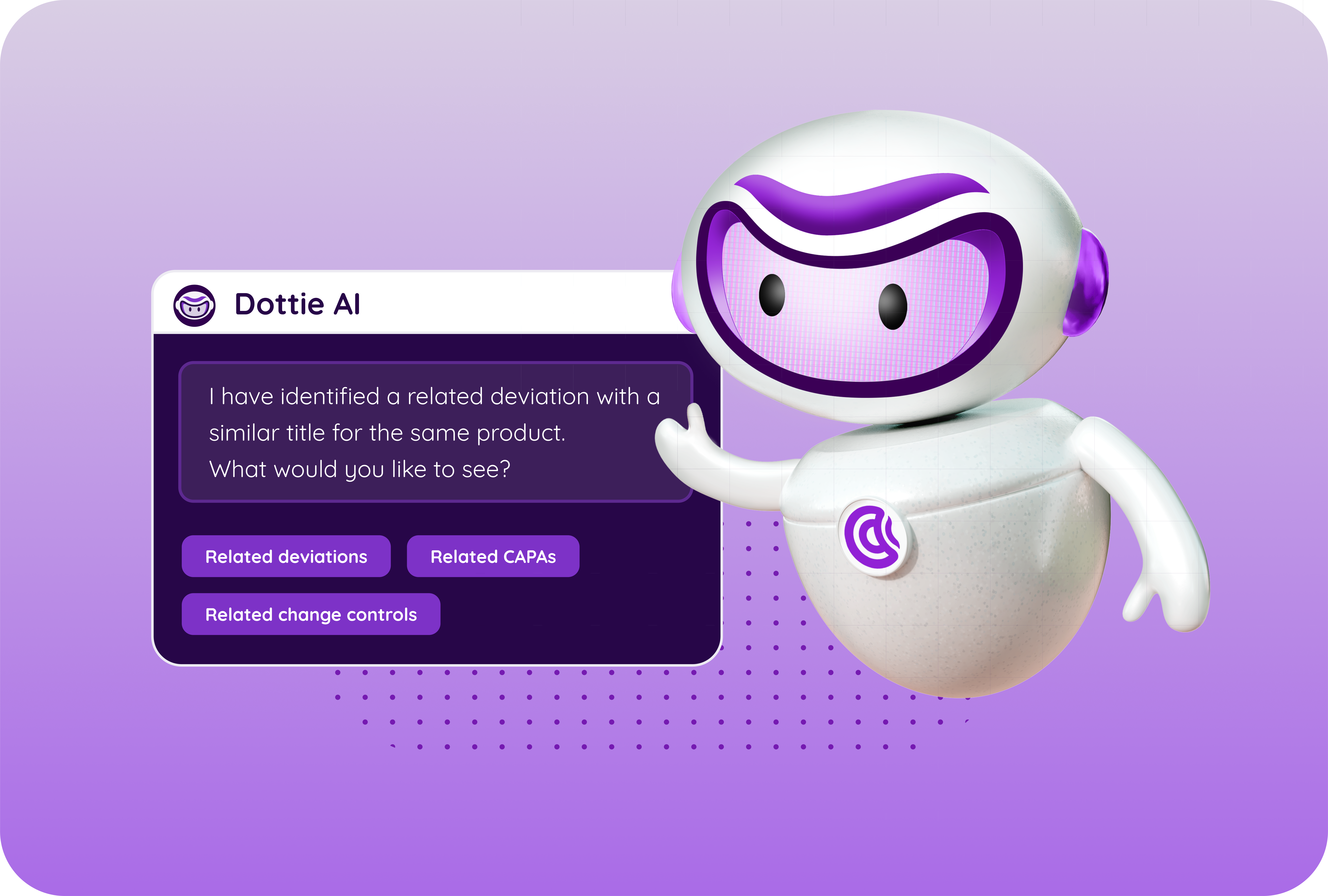

With broad process coverage and integration capabilities, a cloud-based QMS solution allows a company to eliminate redundant point systems (e.g., QMS, DMS, LMS, SQM, EBR, PLM, LIMS, ELN, RA & RIM, etc.) and unite all departments and individuals who impact quality, from internal quality teams out to third party suppliers and partners. The consolidation of quality and compliance data in a single system with future capabilities of Artificial Intelligence (AI) and machine learning enables the quality team to perform advanced analytics to proactively identify and address quality issues.